All about acrylic putty

Content

Universal acrylic putty - repair mortar, which is used to seal joints or eliminate minor defects on work surfaces. Acrylic finishing materials are used to create a facade finish, as well as for indoor work.

Key Applications

Acrylic putty is used in all areas of construction. Depending on the type of this material, the place of use of this building product depends. Key qualities that determine the type and performance of putty acrylic:

- Adhesive qualities;

- Putty should be easy to use;

- Resistance to various damages;

- The ability to protect the surface of the wall or any other work surfaces from UV radiation;

- Resistance to temperature differences;

- Moisture resistance;

- Color and texture of acrylic putty;

- Acrylic layer allows you to "breathe" all surfaces;

- Ecological purity of the material.

Typically, acrylic for interior use is fundamentally different from putty for the facade. You need to choose the material, taking into account all the nuances and features in the planned surface finish.

Composition and key features

The acrylic-based putty is used for leveling deformed surfaces, and also with the aim of preparing the ceiling, walls or floor for painting. To make the acrylic film form, manufacturers use talcum powder. The color is formed by special white.

Acrylic putty for walls is considered more profitable than the plaster type of decoration. The disadvantages of acrylic can be attributed to the unnecessarily fast drying period of about 15 minutes. Also, the use of putty can cause some difficulties in sanding and finishing polishing surfaces.

Among the key advantages are the following:

- Acrylic putty is an excellent protection for floors and other surfaces;

- The acrylic mass itself is very elastic, which contributes to convenient application;

- For the formed putty base, steam transmission is characteristic, but the coating prevents the penetration of water;

- Putty is considered a refractory and environmentally friendly material;

- Quick mastery application of acrylic composition allows you to create an unusually strong integral structure on the surface of floors, ceilings and walls.

In addition to talc, an acrylic waterproof putty for floor and ceiling contains chalk and iborite. The most popular pigments that color the mixture in one shade or another are ocher and some artificial paints.

Species diversity

In fact, all types of finishes are divided into mixtures for internal and external work. However, there is another classification - by the scope of use and the nature of the surfaces to be formed. Acrylic is used in work on:

- Metal;

- Concrete;

- Drywall

- Brick structures;

- Wood products.

It is also worth remembering another form - universal putty. It is used to work with any surfaces and is incredibly popular among domestic builders.

Range

It is worth considering another important classification, which usually plays an important role for a potential buyer. The following forms are characteristic of an acrylic composition:

- Ready mixes. The mass is packed in small plastic containers, tightly packed, ready for use. The product is best bought if a minor redecoration of facade surfaces is planned;

- Dry mixes. The choice in favor of such a moisture-resistant putty is given when you need to work with a large area. The dry mix can be diluted or diluted as desired, giving the most preferred consistency.

In addition to acrylic putties, mineral and polymer analogues are offered to potential buyers on the modern construction market. Mixtures based on silicates and silicone are considered equally popular putties.

About invoices

Acrylic putty on wood, concrete or any other type of surface can not only improve the performance of facades, but also enhance the aesthetic potential of the entire building. Finishing putties are represented by the following textures:

- Bark beetle. This is one of the most popular textures. It is used not only for the finishing of facades, but also inside many rooms. Usually, this is a kitchen, corridor or hallway. The bark beetle looks like a canvas that has been pretty sharpened by bark beetles, leaving characteristic passages. A special grater made of plastic will make the desired effect due to the fact that the granules in the composition can “deform” the surface in a special way;

- "Pebble" acrylic facade putty. The application of this mixture is significantly different from the option described above. Due to the use of specific granules, a pattern is formed on the dried surface of the decorated canvas. It seems that on the surface of the wall are concentrated many pebbles tightly laid next to each other;

- Mosaic putty. Different color crumbs are mixed, transparent resins are added. It is possible to obtain coatings that are universal in terms of operation. Most often, a similar putty is used for the ceiling, decoration of slopes, socles and balustrades. Surfaces can be washed. The tree covered with mosaic putty is not afraid of dust and dirt.

The choice of texture in many respects also depends on stylistic features. For example, the bark beetle is positioned as a universal finish that will fit into any composition, but for mosaic putty it will be more difficult to find application.

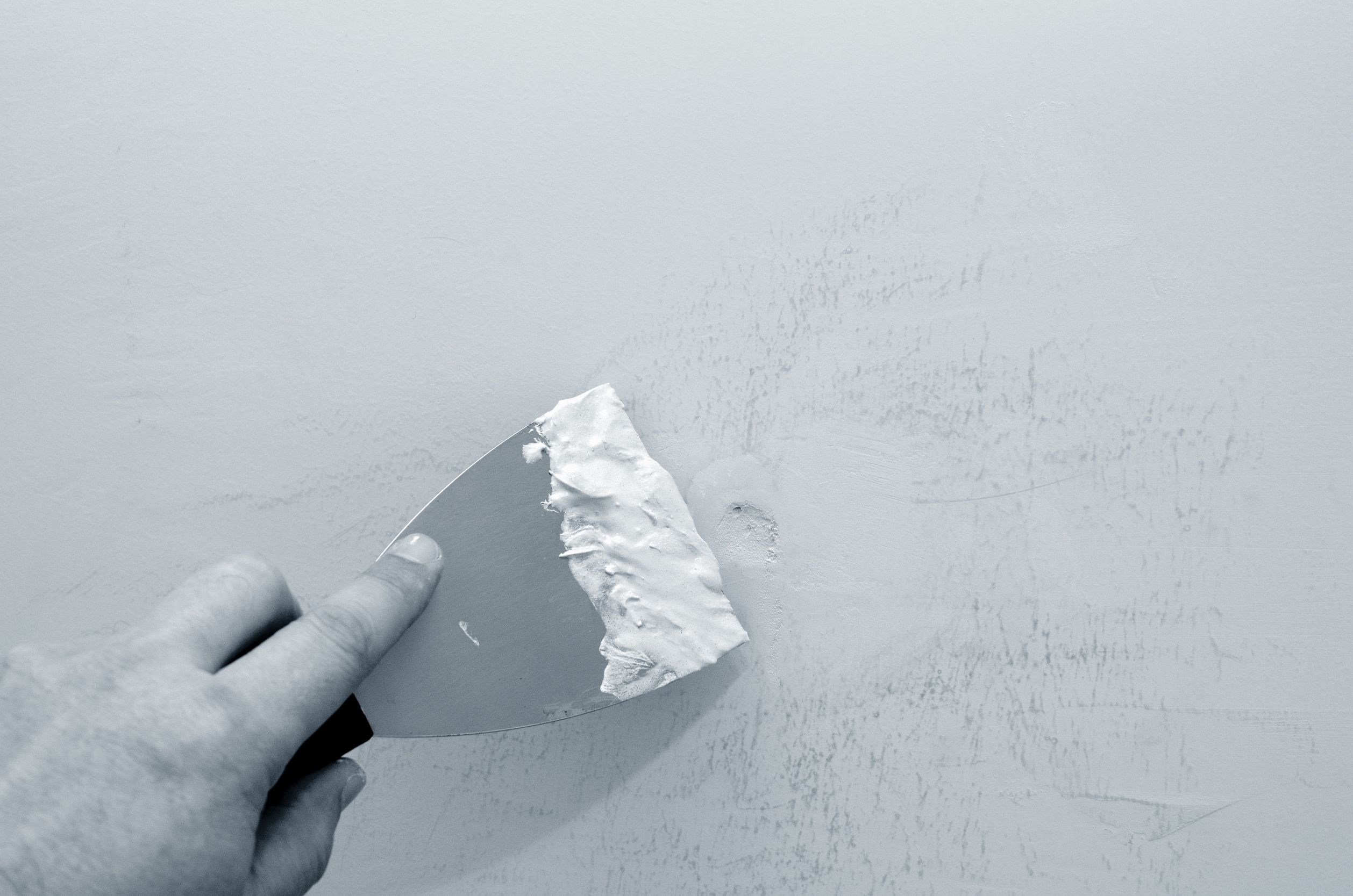

About application technology

Acrylic paint, plaster and any other material for finishing work can be applied in different ways. Finishing putty is applied in two ways: mechanically or manually.

It can be putty using special aggregates. They release the composition under high pressure. The mechanical option is good if you need to arrange large sections. For interior decoration and when working with miniature facade elements, a manual method of decoration is used.

A reinforced mesh is applied to the corners of the facade of any building. Only then can you spread the putty of the desired consistency and get to work. The use of the grid allows you to form really clear right angles, and the coating itself will be strong and holistic.

The algorithm for applying putty on the work surface is as follows:

- The surface is cleaned of any contaminants, smoothed, we clean relief defects;

- The walls are primed with a prepared compound;

- The required amount of putty must be diluted, as required by the construction task. If the composition was originally ready, the mass is still thoroughly mixed;

- When the diluted mixture is ready for use, the master manually or with the help of the unit applies the right amount of acrylic composition to the surface. We staple thoroughly, but quickly. The choice of the method of working with the compositions depends on the texture, which was preferred.

When the acrylic finish putty has already dried up, but still retains its elasticity, a previously thought-out pattern or imitation (for example, bark beetle) is formed on the surface.At this stage, you can not do without a special roller or plastic “grater”.

Subtleties of work

No matter how modern and universal this or that building material is, working with each individual type requires certain skills and knowledge. Masters are happy to share their experience with beginners. Here are the most valuable tips and tricks:

- The minus temperature in the room or outside it (if we are talking about working with facade putty) provokes a sharp decrease in the elasticity of the composition. The best time for applying acrylic compounds is dry and warm weather;

- With acrylic materials it is important not to overdo it. The maximum thickness of the finish layer is 10 mm. The minimum layer is 3 mm;

- Moisture-resistant acrylic putty can be used not only for total wood finishing, but also for the restoration of some products. You can choose a putty that perfectly imitates the wood texture. This is a great alternative to the “classic” wood paint;

- Acrylic compounds for working with metal are allowed. Before applying, both the shade and texture of the finishing material are carefully selected so that it looks organically, complementing the overall finish. If necessary, individual parts are torn with paint.

Volume cavities need to be closed in several stages. If the material is applied immediately with a thick layer, it can spread, giving ugly relief defects. It is better to process the areas in stages, applying thin layers of material. This will allow you to both do the job efficiently and accurately, and save a small amount of material for other sites. The paint is used only when the mixture hardens.

Without experience and lack of necessary practice, it is difficult to do the job accurately, efficiently and quickly the first time. Especially a lot of problems arise if the mixture is selected incorrectly. That is why it is important to use informational or practical support of professionals at any stage.